January 23,2026

January 23,2026

The large-format flatbed printer is a kind of "non-contact with objects" high-tech digital printing equipment of inkjet printing type, which can make color patterns on the surface of any material. Materials and irregular soft and hard objects, such as metal, ceramics, crystal, glass, acrylic, PVC, plastic, toys, leather, U disk, cloth, wood, silicone, etc.

Before using the large-format flatbed printer, the material must be surface-treated, that is, spray a layer of surface treatment agent (coating) on the surface of the material. These treatment agents will not have any effect on the surface of the material, and the effect is to increase the effect and color of the material. of adhesion.

(1) Confirm which material you want to print, and then coat the material.

(2) Before printing, confirm whether the coating is dry or dry.

(3) In addition, it is necessary to ensure that the coating is uniform and clean. If it is not uniform, the ink will not be adsorbed in individual positions, become spots, or bleed. Clean and tidy is also to prevent dust and sundries from affecting the effect after printing and ensure quality.

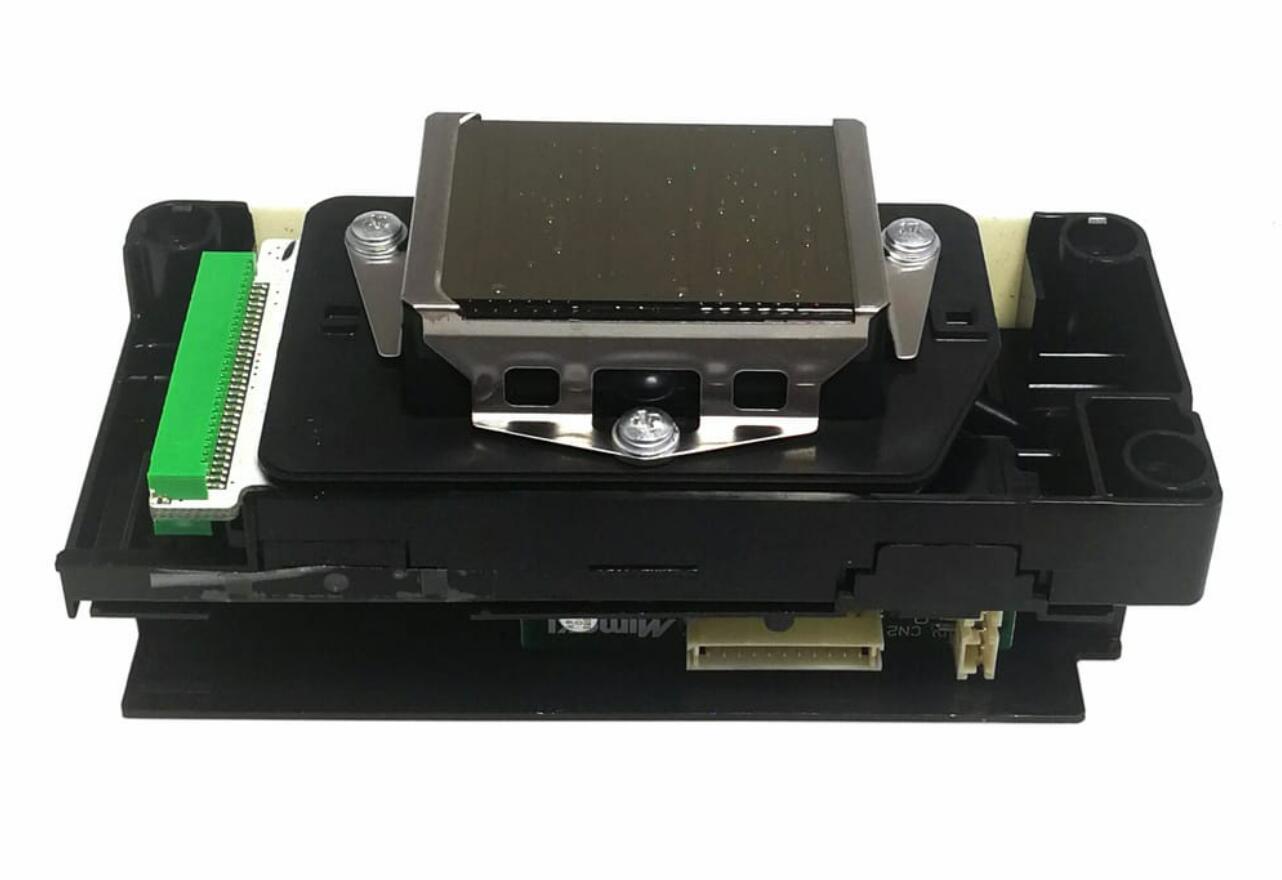

The print head of a large-format flatbed printer consists of many tiny nozzles, and the ejection holes are similar to dust particles. If dust, small debris, etc. enter the nozzle, the nozzle will be blocked, and it is also easy to contaminate the nozzle panel with ink, which will eventually lead to poor ink jetting. Therefore, the maintenance of the print head of the large format flatbed printer is very important. The following points should be done in the daily maintenance:

(1) Do not remove the print head of the large-format flatbed printer from the host and place it alone, especially under high temperature and low humidity conditions. If left for a long time, the water contained in the ink will gradually evaporate, and the dried ink will cause the nozzles to clog. If the nozzle has become clogged, it should be cleaned. If cleaning fails to achieve the purpose, replace it with a new print head.

(2) Avoid hitting the nozzle surface with fingers and tools to prevent damage to the nozzle surface or blockage of the nozzle by debris and oil. Do not blow air to the nozzle, do not put sweat, oil, medicine (alcohol), etc. on the nozzle, which will cause changes in the composition and viscosity of the ink, causing the ink to solidify and block. Do not wipe the nozzle surface with tissue, lens tissue, cloth, etc.

(3) It is best not to turn off the power while the printer is printing. Turn the printer to the OFFLINE state first, then turn off the power when the print head is capped, and finally unplug it. Otherwise, for some models of printers, the printer cannot perform the capping operation, and the nozzles exposed to dry air will cause the ink to dry out.

(1), software cleaning: automatic cleaning through the maintenance function in the printer driver;

(2) Ink cleaning: When the ink cart is in the initial position, use a syringe with a hose to connect the waste ink tube to forcefully extract about 5 ml of ink. If there is a phenomenon of color mixing, if the nozzle protector is not tightly sealed during the ink extraction process, you can gently move the ink cart by hand to ensure a good seal between the nozzle and the nozzle protector. After the ink is drawn, the software is cleaned.

(3) Injecting and pumping cleaning: remove the ink cart, unplug the ink sac, connect the syringe with the cleaning solution to the ink column of the print head with a hose, inject and withdraw with appropriate pressure, until the vertical ejection of the nozzle is complete. Thin line.

(4) Printing cleaning: Use "print head cleaning agent" to replace the ink that clogs the nozzle, use vector graphics software to print the color blocks of the color, and until the print head is blocked, replace the original ink.

For example, the used print head needs to be idle for a long time, and professional maintenance methods and steps for the print head are required:

(1) Disassemble the print head from the printer according to the correct method, and clean the residual ink stains;

(2) Use the print head cleaning agent to thoroughly clean the print head;

(3), inject a special nozzle maintenance agent into each ink column of the print head;