January 23,2026

January 23,2026

The printer will not be so easily blocked when it is used normally every day, because the printer is always in use, the ink will not stay in the needle box all the time, and the ink will rarely solidify in the needle. Conversely, if the printer is not used for a long time, the printer print head is more likely to be blocked. Have you ever encountered such a situation?

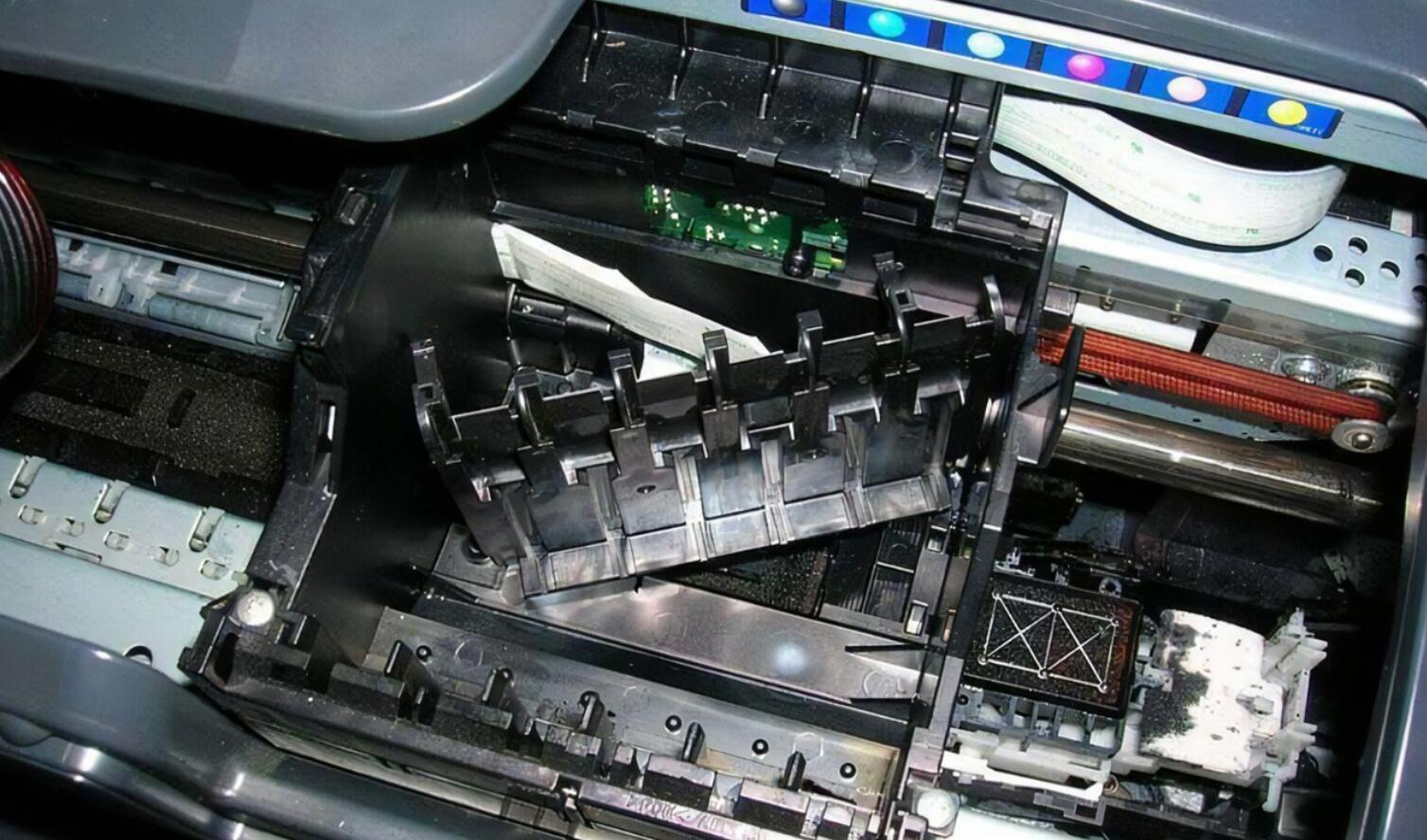

When we find that the content printed by the inkjet printer has broken lines or white streaks, and there is still a lot of remaining ink in the printer cartridge, we must use manual cleaning to remove the ink particles blocked at the printer print head.

When using the manual method to clean the blocked ink printer print head, we first need to carefully take out the ink cartridge installed in the ink cartridge holder, and carefully observe whether there is an integrated circuit part at the bottom of the ink cartridge. The location of this part is actually The location of the printer print head;

Then I found an ordinary teacup, poured some warm water at about 60 degrees Celsius into it, and placed the integrated circuit part at the bottom of the ink cartridge into the warm water for about 20 minutes. We can only immerse the integrated circuit part at the bottom of the ink cartridge in water, but never immerse the entire ink cartridge in water;

When the printer print head part at the bottom of the ink tank is soaked in warm water for more than 20 minutes, we must take the ink cartridge out of the water in time, and then forcefully shake off the water attached to the surface of the printer print head. You will find that some ink will flow out from the position of the printer print head. At this time, we can use a clean cotton gauze to wipe the ink that flows out and then reinstall the successfully cleaned ink cartridge into the ink cartridge holder of the inkjet printer according to the correct method. middle

Finally, we might as well perform the operation of printing a test page to see if the printer print head can work normally at this time. In the actual use of inkjet printers, many printing users often take out the ink cartridges from the printer cartridge holder frequently, which is easy to cause severe blockage of the printer print head, and even part of the ink inside the ink cartridges can also occur. The drying phenomenon, at this time, the printer will generally fail to print.

When encountering such a phenomenon that the nozzle is seriously blocked, we must prepare some alcohol with a concentration of about 95% and a plastic medical syringe and then use a disposable infusion tube to connect the ink supply port of the print nozzle, and then connect the printer print head. The head position of the printer is placed in alcohol with a concentration of about 95%, and then the alcohol is inhaled into the medical syringe through the printer print head, and the blocked ink in the print head can be cleaned by repeating the ink suction operation several times.

Considering that the ink composition produced by different ink manufacturers is different if different brands of ink are often mixed and used together, chemical reactions may occur and particles may be generated. These particles will cause harm to the printer print head, which may easily cause printer The print head to be blocked. Therefore, in order to reduce the number of times that the printer print head is blocked, we try not to change the ink model frequently, so as not to harm the printer print head.

In addition, every time the ink is used up, a new ink cartridge needs to be reinstalled; when installing a new ink cartridge, be sure to control the installation force. If the ink cartridge is pressed into the ink cartridge holder without attention, it is easy to cause deformation of the ink cartridge support mechanism. or displacement, thus affecting the normal spraying of ink; therefore, when installing a new ink cartridge, try to follow the instructions in the inkjet printer's operating instructions to place the ink cartridge into the ink cartridge support mechanism with appropriate force, instead of using brute force to break the ink cartridge support.

1. Use a damp soft cloth to remove dust, smudges, ink stains, and paper scraps inside the printer.

Special attention: Pay attention to cleaning the drive shaft of the trolley. Use a dry absorbent cotton swab to wipe off the dust and oil on the guide shaft.

2. Put two drops of sewing machine oil on the drive shaft.

Special attention: When cleaning, be careful not to wipe the gears, the area near the print head and the ink cartridge, do not move the print head and do not use volatile liquids such as thinner and gasoline.

3. Open the upper cover of the printer, and you will see that there is a relatively smooth iron rod in the printer, which is called a guide rod in the industry. There is lubricating oil on it, which is the track on which the printing head runs. Due to the cold weather in autumn and winter, the lubricating oil is very It is easy to solidify. In addition, if the machine is not maintained in daily use, the guide rod will be constantly invaded by dust, etc., and it is likely to hit the head once it reaches the cold winter.