January 23,2026

January 23,2026

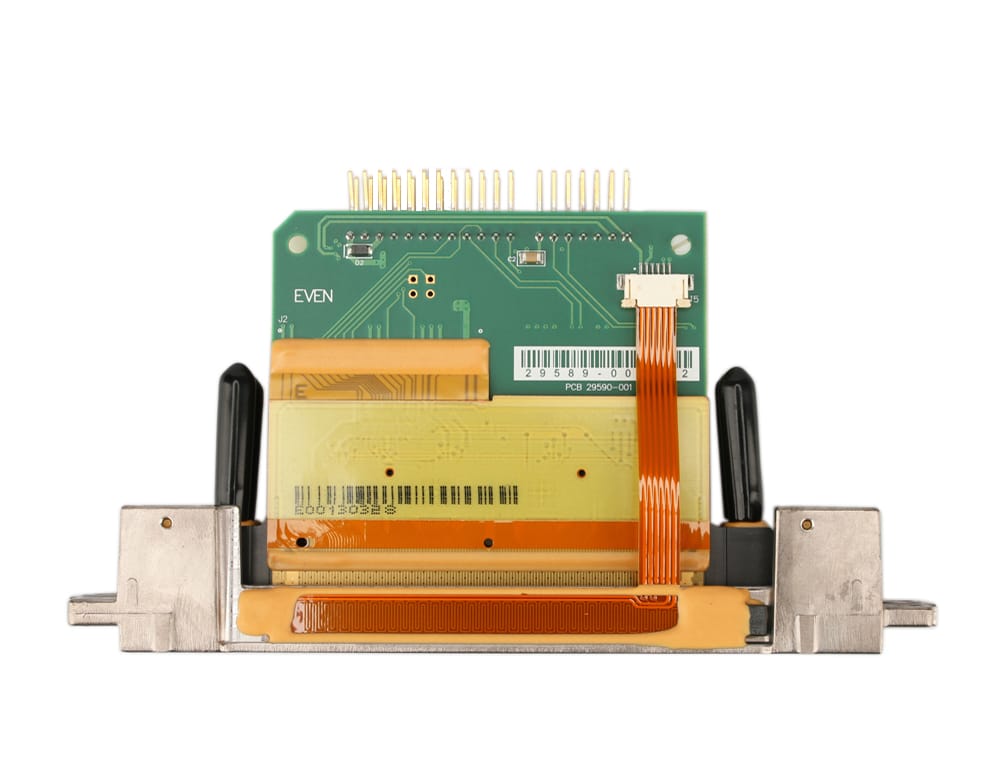

When it comes to printer products, we are no strangers. Whether it is work or life, as long as printing is involved, printer equipment is inseparable. As one of the indispensable pieces of equipment for company offices and home offices, the printer has greatly improved people's quality of life. Work efficiency is an important part of the printer, and the maintenance of the print head is very important. Then the print head, some people will encounter the situation that the print head is blocked in the process of using the printer. Why is UV Printer Nozzle Blocked? Here are some reasons to analyze

1. The piezoelectric crystal is damaged: the print head must not be able to inkjet. Generally, the piezoelectric print head can be used for about one year. For a factory with a heavy inkjet printing workload, less than a year of use may be normal.

2. The filter in the Printer Nozzle Blocked is clogged, and the print head does not produce ink: If the print head is used for a long time, especially in factories that are not satisfied with the printing task and often shut down at night, the ink will not flow into the print head for a long time, and it is easy to be adsorbed on the internal filter. On the screen walls or ink passages, reducing the cross-sectional area of the ink flow can also cause the ink to flow out of the nozzle.

3. After the ink has accumulated to a certain extent, the nozzle is blocked outside: this is a common method of plugging because the solvent in the ink must be evaporated into the air to dry the picture, so the ink is a volatile liquid, which can Use in the air. Volatile transparent solid. When the nozzle hits the cloth, there is always some ink left around it. After this part of the ink is dried in the air, the nozzle will gradually become smaller or even block the nozzle, which needs to be cleaned frequently.

4. Fatigue damage to piezoelectric crystals: the phenomenon is that the nozzle sometimes emits ink, but sometimes it does not, especially when the amount of ink is large

5. Drive circuit failure: The electronic components of the drive circuit are aging, and the dry ink is too dirty, which may affect the voltage of the drive print head, resulting in unstable ink output or ink volume from the Printer Nozzl

6. Types of inks: Some manufacturers' inks dry too fast due to improper control of the amount of desiccant, which may easily cause ink blockage. Although it can be cleaned, the cleaning interval is more frequent. Once the nozzle is not used for a long time, it is not timely. When protecting the printhead, it may cause permanent damage to the printhead the next time it is repainted. If the nozzle is not used for a long time, it is recommended to take protective measures such as regular flash spraying and printing test paper.

7. Frequent ink replacement: In many cases, the nozzle may not be properly protected when replacing the ink, which will also affect the inkjet state of the UV Printer Nozzle.

8. The viscosity of the ink is too high or too low: the viscosity of the ink is too high, the fluidity of the ink is poor, and the amount of ink ejected by the nozzle per unit time is not enough; the viscosity of the ink is too low, that is, it is too thin, and it is easy to be pressed in the nozzle. When the triode is pulled out, the air is sucked in, but the ink cannot be sucked in, so the air is ejected; both will cause the phenomenon that the nozzle has no ink.

9. The ambient temperature and humidity used by the machine: generally recommended temperature is 22~25 degrees, humidity is 40~70%, and the density of air dust and impurities should be below, on the one hand, to avoid nozzle blockage, on the other hand, it also Improved print quality. High and low temperatures affect the viscosity of the ink, which will cause ink shortage or print head tailing, which is often mistaken for "nozzle blockage".