January 23,2026

January 23,2026

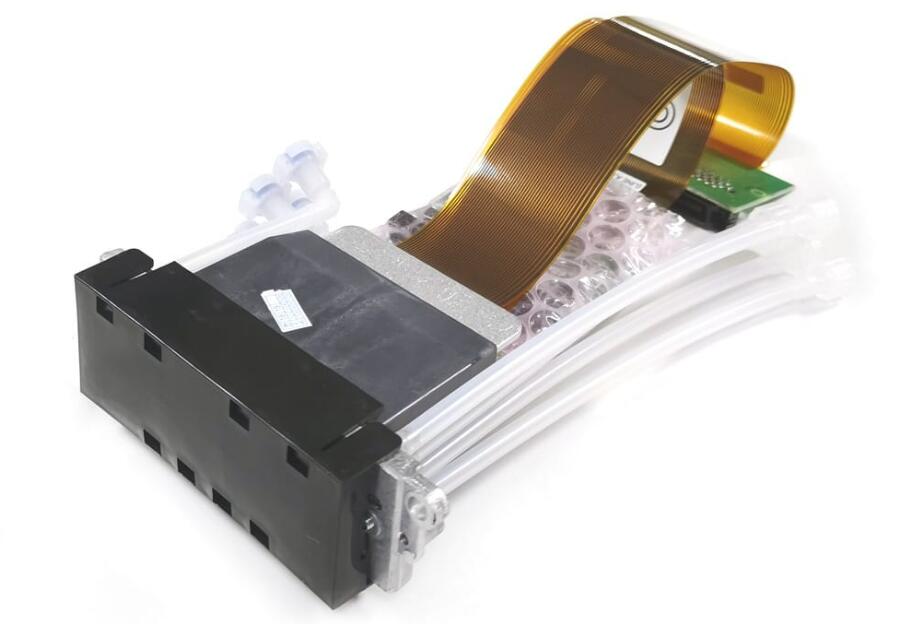

Ricoh has established 11 R&D centers and laboratories in the United States, Europe, China, and Japan, with more than 3,500 scientists, researchers, and engineers. Each R&D center or laboratory is dedicated to conducting research in a specific area. The technical requirements of Ricoh print heads are much more accessible. Of course, the market price is not expensive. It is suitable for some large-scale production and processing. The service life of Ricoh print heads is between 8-12 months.

gen4l series grayscale print head 384 nozzles There are mainly five models, which are used in nano silver circuit board printing.

gen5 /7-35pl, 1280 nozzles, 8-level grayscale, ignition frequency: 60khz, suitable for water-based, solvent, oil-based, UV ink.

gen4l/15pl ignition frequency: 30khz

gen4l/27pl ignition frequency: 30khz

gen4 series grayscale print head 384 nozzles mainly include:

gen4/7pl ignition frequency: 30khz

gen3 e3 series: 192 nozzles The main models are

gen3 e3/15pl

gen3 e3/30pl

gen3 e3/45pl

gen3 e1 series: 92 nozzles, ignition frequency 30khz

gen3 e1/30pl

gen3 e1/65pl

The above are some basic parameters of the Ricoh printhead. Compared with other industrial printheads, the printhead has 7pl ink droplets, which is a type of industrial printhead with high precision. It is the same as the Seiko gs1024 printhead. The disadvantage is that the number of orifices is too small. is very slow.

1. The Ricoh print head is a gray-scale piezoelectric print head, variable ink drop printing, small 7pl, large 35pl, photo-level precision, can print 2pt fonts clearly, high-resolution 1200dpi*600, or 1200*1200 12pass printing, The positioning of the nozzle trolley adopts a fixed linear grating to ensure high-precision printing positioning. The light platform makes the plate transfer easier, the positioning more, and the repeated printing is without deviation.

2. The Ricoh print head itself is made of all-steel nozzles, which are not easy to corrode or block the nozzles. The nozzle cleaning method is a piston cleaning method during automatic cleaning, which is not easy to cause damage to the nozzles. The nozzle and the cable are integrated. The contact between the cable and the nozzle is stable, and there is no problem with a loose cable. The Ricoh print head can print in single and double rows, the ink control is excellent, and the variable single and double rows can also print quickly and slowly.

3. The Ricoh print head adopts intelligent x-direction and y-direction white jump printing, which automatically recognizes blank areas and quickly skips them. It supports multiple copy printing and area printing, which is convenient for batch printing of small pictures and sampling printing of large pictures. Supports resume printing, which is used to resume printing for the printing task that the user stops the printing task or exits due to an error during the printing process. Support mirror printing function to realize double-sided printing. Double zero positioning function (double starting point printing), the printer can print from the beginning to the end. Realize reverse printing and forward and reverse alternate printing, further improve production efficiency, and will not waste a little useful material.

4. Humanized design, automatic medium thickness measurement, and automatic height control system adopt a fully closed-loop control method, which can automatically adapt to different thicknesses of media and avoid damage caused by human error. It has the automatic white skipping printing function that significantly improves production efficiency, can automatically identify and avoid blank parts on the screen, can set the irradiation power of two UV lamps, and automatically rotate according to the round-trip direction during bidirectional printing, which can effectively reduce the depth pass. The powerful nozzle compensation function can replace the faulty nozzles with normal nozzles for inkjet printing to ensure that the screen will not appear white or pass. Equipped with powerful intelligent and user-friendly rip software, different pictures can be output after overlapping. It greatly facilitates the daily proofing and color matching work, and the shipping efficiency is greatly improved. The optional software template printing technology solves the error problem in the splicing, making the splicing error less than 0.5mm, the optional assembly line printing mode is suitable for the industrialized online generation, and the trolley medium anti-collision device can automatically stop when it encounters the medium, protect the trolley print head.

5. Stable and reliable, the full range of digital printing equipment is designed according to the 24-hour*7-day generation operation mode, and various durable parts that meet the requirements of industrial production are selected, especially the use of industrial-grade nozzles only need careful use and maintenance. last 3-5 years. The use of igus towline, fuji servo motor, and Megaudi synchronous belt ensures long-term stable and reliable operation of the system. The equipment is equipped with multiple emergency brake switches to ensure the safety of people and equipment. A variety of printhead standby protection schemes are available to realize the combined application of flash jetting, squeezing ink, and high-speed flash jetting, so that the printhead is always in the best working condition during printing. The jet truck adopts a fixed linear grating to ensure high-precision printing and positioning.

6. The ink saving is as high as 30%-50%. Due to the variable dot technology of the gray-scale nozzle, the four-color printing effect is the same as the six-color printing effect without the gray-scale nozzle. The reason is that when the nozzle without grayscale is printing, the color is dark. Where the color is dark, such as key, it will be printed in light colors, such as MLC, but whether it is dark or light, the size of the ink droplets from the nozzle is the same, just because the light The contribution of color to color is relatively small and it is only lighter, but the Ricoh print head adopts grayscale printing. It will use 21pl to print in dark places, 14pl to print in lighter places, and use 14pl to print in very light colors. The place uses 7pl printing, that is to say, the grayscale printing technology adapts the color depth of the image by adjusting the size of the ink droplets so that the use of ink can be reduced, while the ordinary printing is to increase the light color ink to adapt to the color depth of the image. changes, the amount of ink used will be larger.

7. Eco-friendly, VOC-free (Volatile Organic Compounds) eco-friendly UV-curable ink - the new trend of the future! Wide range of applications Because UV curing ink can be directly printed on various materials, it can partially replace the application of traditional silk screen printing, and obtain richer colors and higher efficiency than silk screen printing, so it can break through the traditional process and achieve personalized product processing. It has developed rapidly, such as glass, acrylic, wood, ceramic tile, metal plate, PVC board, corrugated board, plastic, etc.