January 23,2026

January 23,2026

Inkjet technology utilizes tiny droplets of ink to facilitate direct printing without the device coming into contact with the printing surface. Because the technology supports non-contact printing, it can be applied to various media and is now being introduced into a wide range of fields from general-purpose to industrial. The simple structure combining the inkjet print head with the scanning the mechanism reduces equipment costs. In addition, because they do not require a printing plate, inkjet printers have the advantage of saving print setup time compared to traditional printing systems (such as screen printing) that require fixed print blocks or plates, etc.

There are two main ways of inkjet printing, namely continuous inkjet printing (CIJ, continuous ink flow) and drop-on-demand (DOD, ink droplets are only formed when needed); drop-on-demand is divided into three different categories: valve inkjet (using needle valves and solenoids to control the flow of ink), thermal foam inkjet (the liquid flow is rapidly heated by micro-heating elements, so that the ink evaporates in the print head to form bubbles, forcing the printing The ink is ejected from the nozzle), and there is piezoelectric inkjet.

Piezoelectric jet printing technology uses piezoelectric material as the main active element inside the printhead. This material produces a phenomenon known as the piezoelectric effect, where an electric charge is created when a (natural) substance is acted upon by an external force. Another effect, the inverse piezoelectric effect, also occurs when an electric charge acts on the substance, which deforms (moves). Piezo print heads feature PZT, a piezoelectric material that has undergone electrical polarization processing. All piezoelectric printheads work in this same way, deforming the material in order to eject ink droplets. A printhead is an integral part of a printing system with nozzles that eject ink. Piezo printheads consist of an active component called a driver, with a series of lines and channels forming a so-called "liquid path", and some electronics to control the individual channels. The driver contains some parallel walls made of PZT material, forming the channels. An electrical current acts on the ink channel, causing the channel walls to move. The movement of the ink channel walls creates acoustic pressure waves that force the ink out of the nozzles at the end of each channel.

Now the mainstream nozzles used in the UV inkjet printing market are GEN5/GEN6 from Ricoh, Japan, KM1024I/KM1024A from Konica Minolta, Kyocera KJ4A series from Kyocera, Seiko 1024GS, Starlight SG1024, Toshiba CA4, Epson Japan. There are others but not introduced as mainstream sprinklers.

Commonly known as the GEN5/6 series in China, other parameters are basically the same, mainly because of two differences. The first and smallest 5pl ink droplet size and improved jetting accuracy can produce excellent print quality without graininess. With 1,280 nozzles configured in 4 x 150dpi rows, this printhead enables high-resolution 600dpi printing. Second, Greyscale's maximum frequency is 50kHz, which increases productivity. Another small change is that the cable is separated. According to the manufacturer's technician, it was changed by some people on the Internet who attacked this cable defect. It seems that Ricoh still cares about the opinions of the market! The market share of Ricoh print heads should be the highest in the UV market. There must be a reason for what the people want, the precision is representative, the color is good, the overall matching is perfect, and the price is the best!

An inkjet printhead with a full-nozzle independent drive system with a multi-nozzle structure capable of discharging from all 1024 nozzles simultaneously. The high-density structure features a high-precision alignment of 256 nozzles in 4 rows for improved positioning accuracy for high-definition print quality. The maximum drive frequency (45kHz) is approximately 3 times that of the KM1024 series, and by using an independent drive system, it is possible to achieve approximately 3 times higher drive frequency (45kHz) than the KM1024 series. This is the ideal inkjet printhead for developing single-pass system inkjet printers capable of high-speed printing. The newly launched KM1024A series, up to 60 kHz, with a minimum accuracy of 6PL, has greatly improved in speed and accuracy.

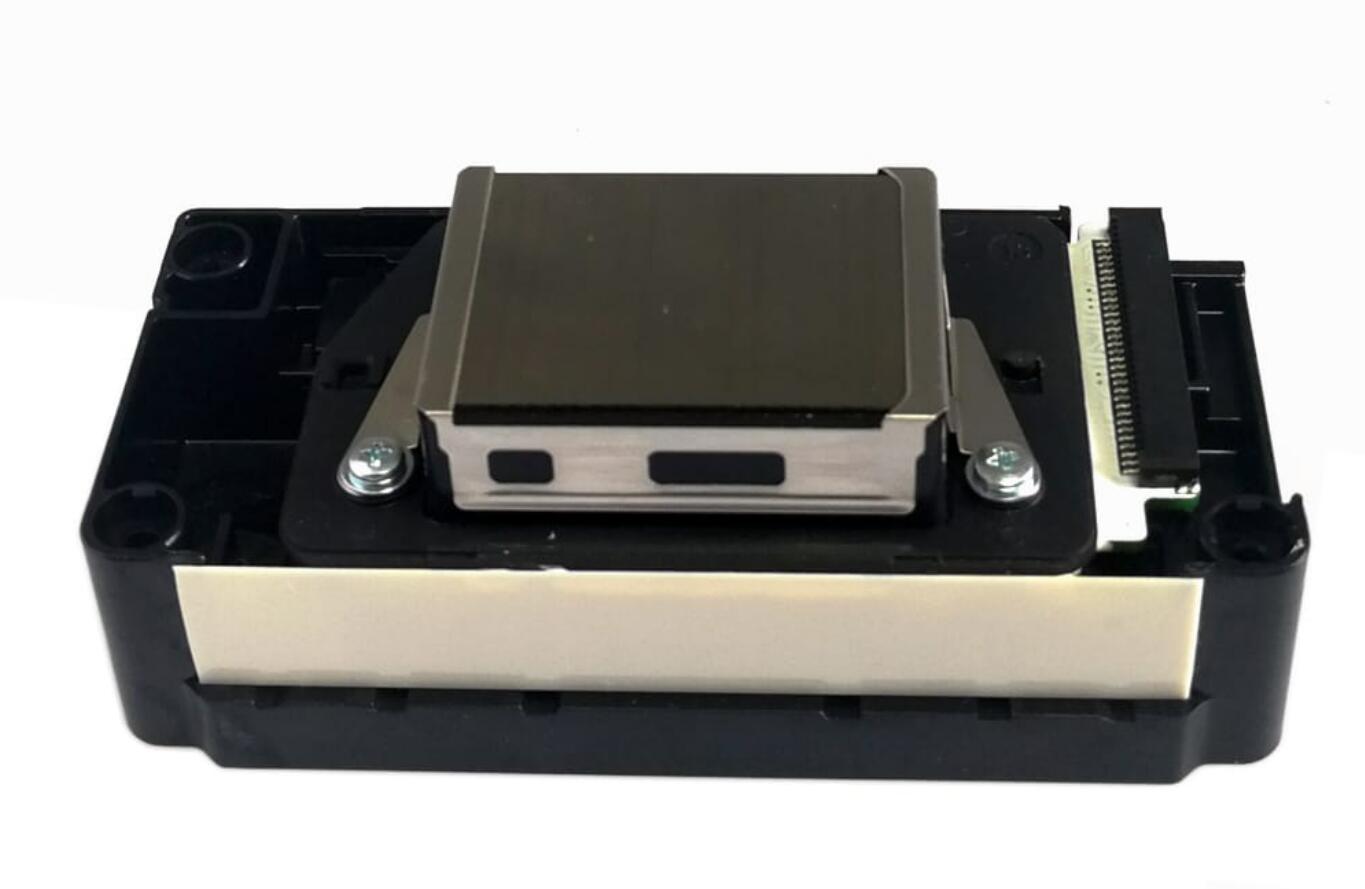

Epson is the most widely used and well-known print head, but it has been used in the photo market before. The UV market is only a few manufacturers of modified machines doing modified games, and more of them are used in small desktop machines to focus on accuracy, but The mismatch of ink leads to a greatly reduced service life, and there is no mainstream influence in the uv market. However, in 2019, Epson developed a lot of permissions for print heads and released new print heads. At the Guangdi Peisi exhibition at the beginning of the year, our booth at Epson You can see this print head in the poster.

Uv equipment itself is production equipment, which is a large-scale production tool. The production tool should have, stable and easy to use, have a low cost of use, fast and perfect after-sales maintenance, and pursuit of cost performance.